The enterprises waste gas can produce organics with Sulfur, Nitrogen (such as Hydrogen Sulfide and Ammonia) and Low molecular fat, Amines, Mercaptan, Thioether and Indole. Its complicated components are very difficult to deal with.

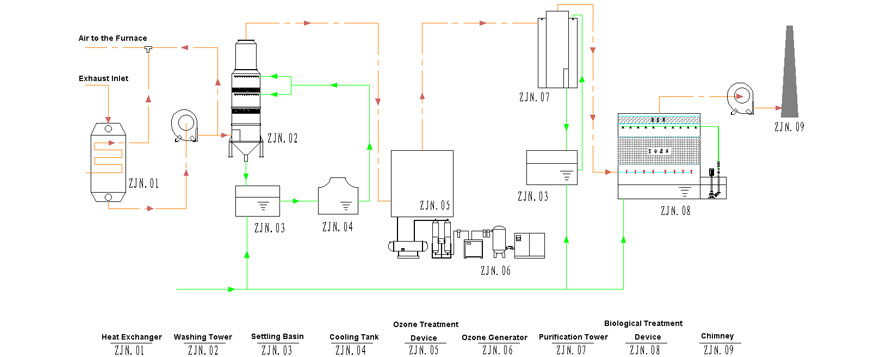

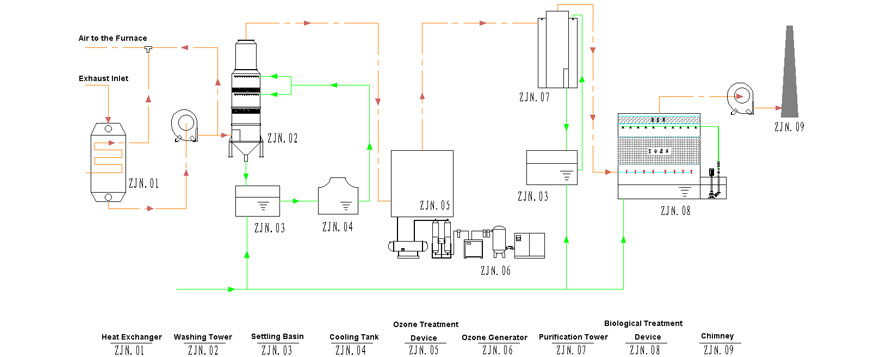

With advanced processing techniques, our Four-in-one Multi-functional Waste Gas Treatment Equipment uses the technique of “Combustion + Washing + Ozone + Biological Treatment”. It is a good solution for the exhaust.

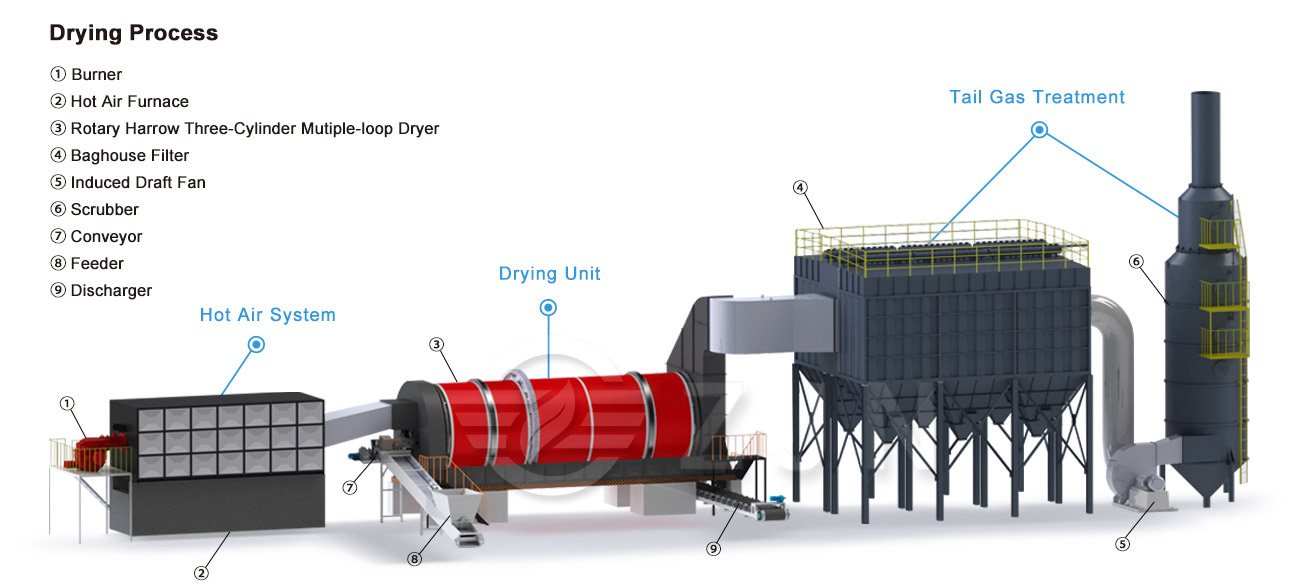

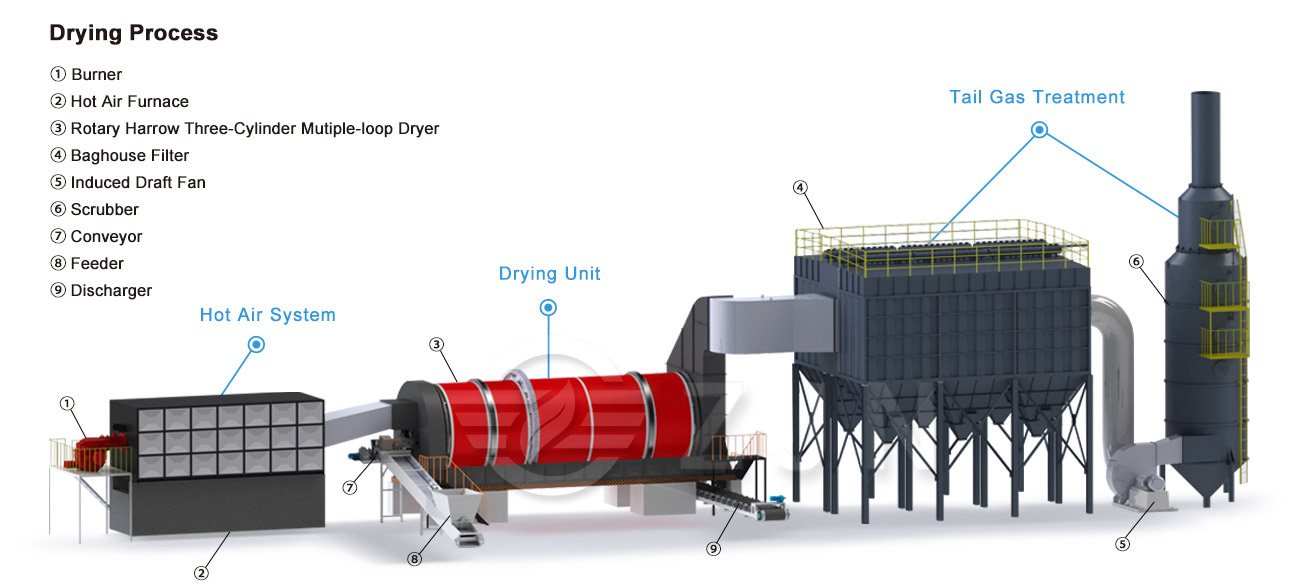

It works as follows: Firstly, utilizing the combustible gas in the exhaust. Sending the exhaust into the furnace, the combustible gas will burn, thus being eliminated. Secondly, sending the other exhaust to Ozone treatment device. In the role of Ozone Generator, large number of O3 will be produced. Then the Low valence Nitrides and Sulfides will be oxidated into high valence compounds. Thirdly, removing acidic materials through Alkali Scrubber. Fourthly, sending the processed exhaust into the Biological Treatment Device. The microbial cells adsorb the odorous substances in exhaust as their nutritional food. And the degrading and metabolic types are diverse. With this character, the exhaust will be broken into H2O, CO2 and other stable inorganic matter. Thereby the exhaust will be completely purified!

Through the above four different processing techniques, the poisonous, harmful and smelly exhaust (such as Nitrogen compounds, Sulfur compounds, Oxygenate, Hydrocarbons, Halogen and their derivatives) can be efficiently controlled. With Four-in-one Multi-functional Waste Gas Treatment Equipment, the waste gas will be harmless. Enterprises can easily reach the exhaust emission standard. Therefore, the earlier you deal with enterprise exhaust, the earlier you benefit from it. The environmental protection can also convert to enterprise development advantages.