Industrial Sludge Drying Equipment

Living Sludge Drying Equipment

Dregs Drying Equipment

Pulp Drying Equipment

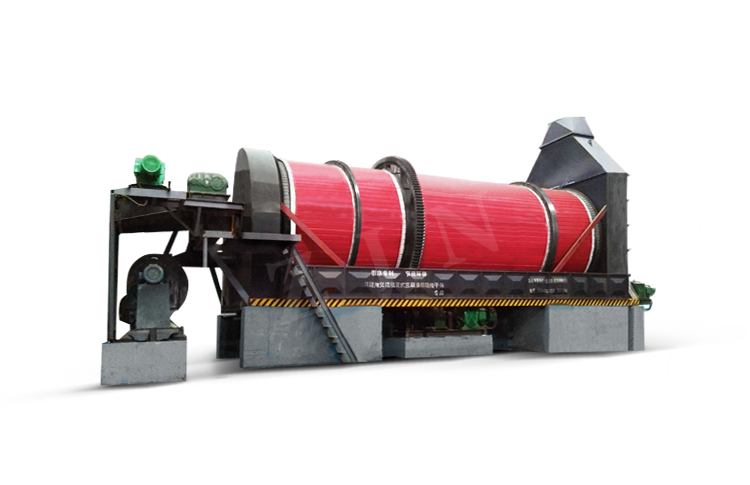

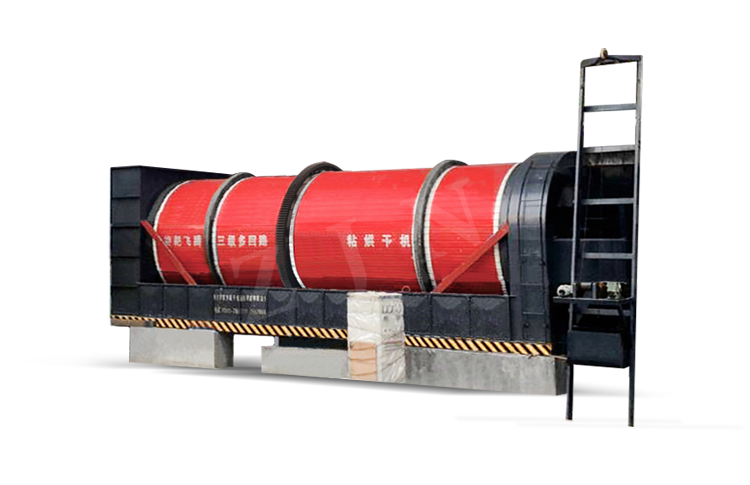

Mining And Chemical Drying Equipment

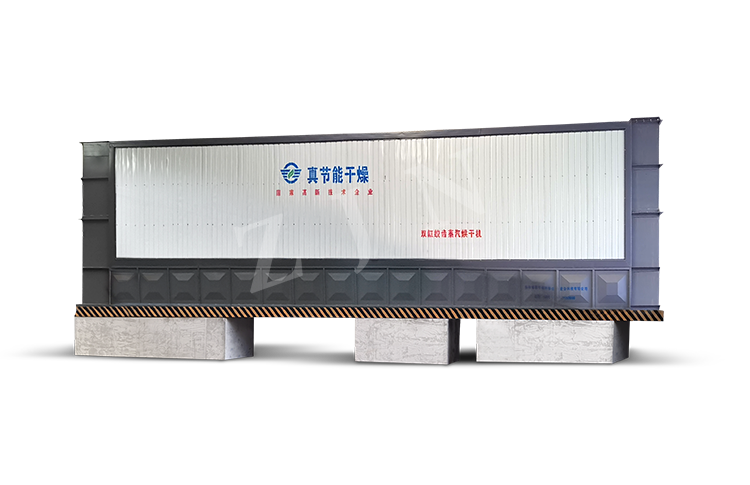

Solid Waste Drying Equipment

Steam Drying Equipment

Fertilizer Drying Equipment

Accessories

Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd. established in 1991, is a state-level high-tech enterprise engaged in drying technology research and development and equipment production.

Read MoreJiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd. founded in 1991, is a national high-tech enterprise engaged in drying technology research and development and equipment production.The main products are sludge dryer, steam dryer, pulp dryer, dregs dryer, waste heat utilization dryer, chemical and mining dryer and other large-scale drying equipment and dryer auxiliary equipment.After 30 years of growth and accumulation, the company has more than 100 national patent technologies, and its business covers more than 20 provinces and regions in China and many countries and regions in the world.

The company has more than 100 national technology patents,Won the national high-tech enterprises, small and medium-sized science and technology enterprises in Henan Province and other honors.

With the cooperation of Henan University of technology and other universities, we have established a fully functional drying technology and equipment engineering technology research center.

Professional after-sales service team, 24-hour service hotline, equipped with full-time after-sales service engineers; Quality oriented, integrity first, customer-centered, regular maintenance.

After 30 years of growth and accumulation, the company's business covers more than 20 provinces in China and many countries and regions in the world.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.