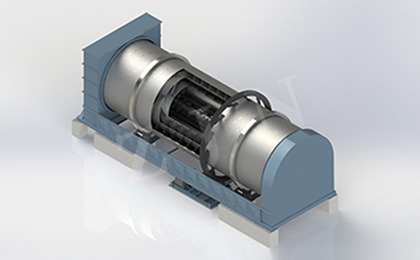

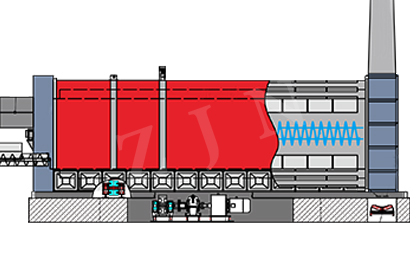

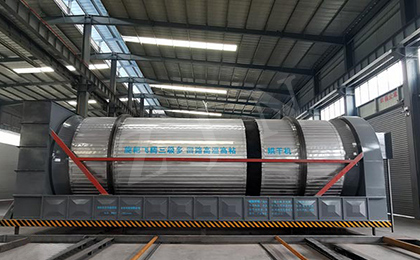

The use “Triple Stage & Multi-loop Patent Technology”, which pack three cylinders with different diameters together, so that wet material can spread thinly with big evaporation area, in order to dry fast.

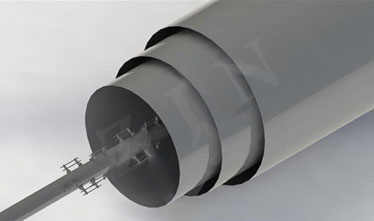

With this crushing device, constantly rolling, rotating and separating, so that the wet material surface forms a “dry shell”, effectively avoiding the particles from agglomerating again.

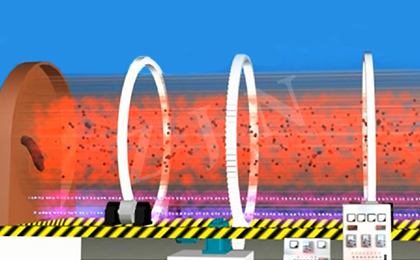

The use of Triple “W & S” Material Movement technology, wet material under go a long distance in the drying equipment, thus it can contact with the hot air adequately, there by the hot utilization rate will be high.

The use of “Downstream and counter flow Reciprocation” patent technology.Wet material go back two steps after taking three steps in the dryer.And the dry ones move fast, the wet ones slow. The day material will discharge automatically once the material meet the drying request.

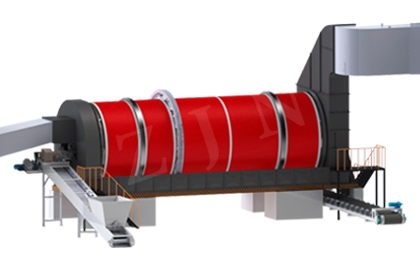

Particular “Hot Air Distribution System”, can adjust the hot air volume into the triple stage dryer.

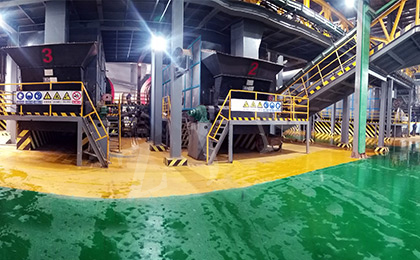

The use of “Mechanical Material Feeding Technology” , wet material in the Material Feeding System can go forward and backward automatically.

The use of “Automatic Material Feeding Control Configuration”. To control the feeding amount on basis of the wet material moisture.

The use of “Automatic Reciprocating Material Technology”. It can make the wet material mixed and tumble, then fully separated into bulk and linkage integrated production.

“Three Cylinders Grading Exhaust Process”, the water vapor produced during drying process can be discharged in time just to avoid the re-adsorption.

The use of “Forward and Reverse Feeding and Raising System”.Wet material can move in multiple directionsin the cylinder, cover the entire dryer and form a material curtain. Wet material can go everywhere in the dryer and contact with hot air adequately.

The use of “Low Temperature but Large Air Volume” drying technology. In the role of low temperature, wet material can make full use of large volume air for drying so as to meet the requirement of drying.

“Speed Adjustment and Control Device” for main dryer, which is a device for adjusting the finished material moisture on basis of the requirement in order to meet drying demands.

“Negative pressure” working condition, safely and clean work site and operating reliably.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.