All Dryers Are Customized

Engineers available to offer overseas service

All Year Round After Sale Hotline

Free Remote Technical Support and Train

Warranty: 1 Year

Certification: ISO9001

Application: Municipal Sludge drying, City sludge drying, Sewage sludge drying, Stinky mud drying, Smelly sludge drying, Dewatering, Boiler flus gas, Waste Heat Utilization

Before Drying

After Drying

Municipal sewage sludge is created for a good reason - it is the by-product of processes that clean our raw sewage before the cleaned effluent is discharged into receiving water bodies, e.g. seas, streams and estuaries. Municipal sewage contains not only human faeces waste but also products and contaminants from homes, industries, businesses, storm water, landfill leachate (in some locales) and contaminants leached from pipes. Sewage sludge as an end-product of wastewater treatment processes reflects the composition of the raw wastewater and therefore anthropogenic activities in the treatment plant’s sewerage system catchment.

Due to the physical and chemical processes involved in the treatment, the municipal sludge tends to concentrate trace metals, many of which are heavy metals, and poorly biodegradable trace organic compounds as well as partially pathogenic organisms (viruses, bacteria) present in the wastewater. Sludge is, however rich in nutrients such as nitrogen (N) and phosphorous (P) and contains valuable organic matter that is potentially useful for amelioration of soils that are depleted or subject to erosion. The organic matter and nutrients are two main elements that make the spreading of this kind of waste on land suitable as a fertilizer or as an organic soil improver, usually after hygienic treatment and or composting. Furthermore, utilization of sewage sludge as a fertilizer may replace or at least reduce the use of mineral fertilizer in agronomic plant production.

Municipal sludge relates to people living environment and health. It is necessary dry them. However, municipal sludge is high humidity and strong viscosity and easily to bond again, traditional drying machine can’t dry it completely.

Our drying equipment is triple stage and multi-loop rotary drum dryer for municipal sludge. We specially designed rotary harrow, hot air distributor and discharging system, W type guiding and lifting boards, S Type transporting way, three levels cylinders etc, and have over 100 patent technology. With the combination function, it efficiently prevents sludge bonding again or bonding to the cylinders, heating energy is fully used, drying speed largely increased, thus sludge will be dry more completely as request!

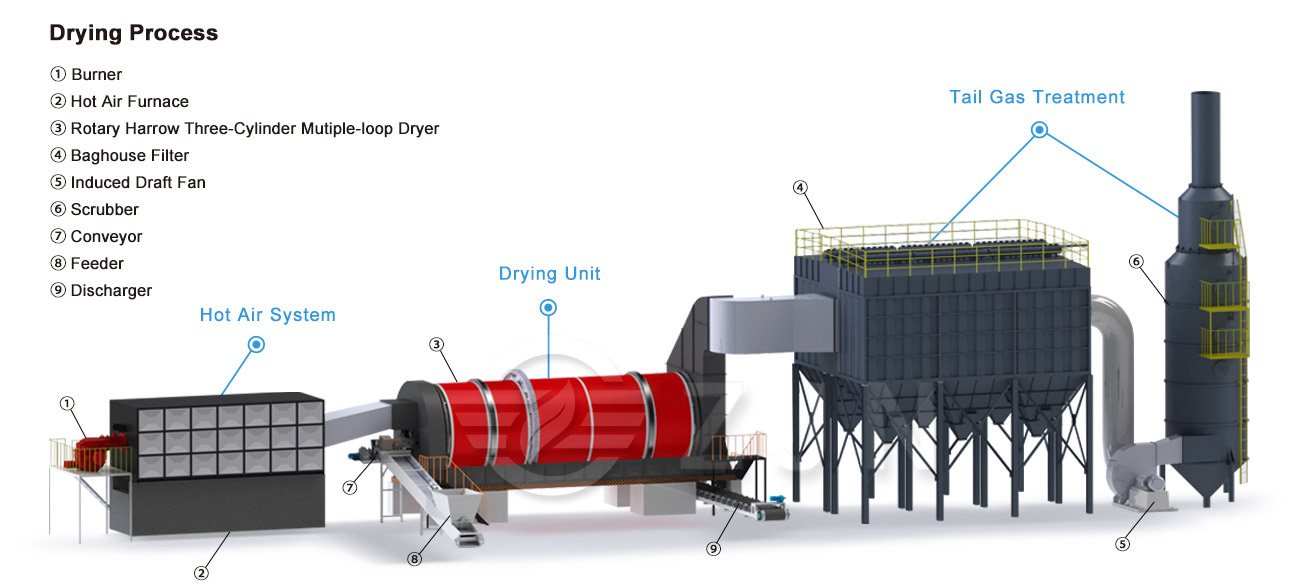

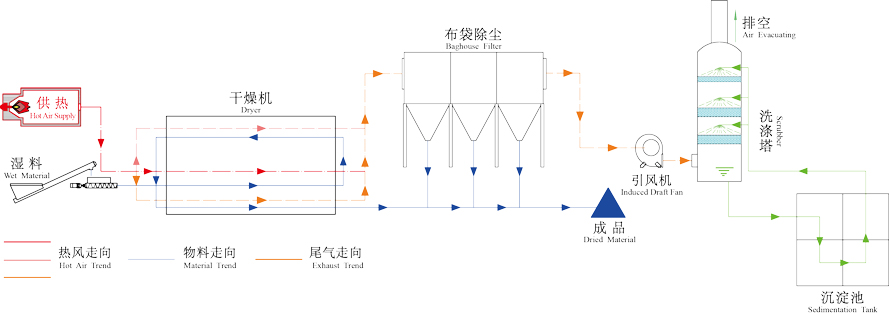

Sludge dryer production line generally includes the following system devices: heating system, conveying device, feeding system, discharging device, induced draft system, dust collector equipment, sludge dryer, instrument control system, etc.

ZJN sludge dryer is made of wear-resistant and high temperature resistant stainless steel, which has better quality and longer service life than ordinary steel. The equipment can use natural gas, steam, biomass particles, fuel oil, coal, boiler exhaust and other heat sources for heating. From the appearance point of view, the main body of the sludge dryer adopts a multi return structure, which is shorter than the traditional single drum dryer, occupies a smaller area, and is convenient for installation and disassembly. It effectively solves the problems of easy adhesion and wall sticking in the drying process of high humidity and high viscosity sludge. The new internal structure of the cylinder greatly expands the application scope of the equipment, making ZJN sludge dryer suitable for drying different types of high humidity and high viscosity sludge in many industries.

In addition, ZJN provides users with perfect customized service of sludge dryer. According to the characteristics of materials, output, drying degree, site size and other requirements, scientific and reasonable drying scheme can be designed to meet the diversified drying needs of users.

During the production process of ZJN sludge dryer, the wet sludge is transported into the drum through the feeding device. The "rotary rake crushing" dispersal device set in the drum first breaks the sludge into small particles, then, under the rotation of the combined lifting device, the material is constantly thrown up and scattered, and the uniform material curtain is lifted on the cross section of the cylinder. The area of heat exchange is greatly increased, the evaporation intensity of the equipment in unit time is greatly increased, the heat energy is effectively used and the heat loss is reduced. Therefore, ZJN sludge dryer will work efficiently and dry well.

The special exhaust mode can effectively avoid the phenomenon of moisture return at the end of the material and uneven drying. The whole drying process can be divided into three stages. While the sludge evaporates rapidly, the water vapor can be discharged from the end of each stage of drying. Compared with traditional drying equipment, ZJN sludge dryer has faster breaking speed, more scientific and reasonable arrangement of lifting device, making wet materials not easy to stick to wall and agglomerate in drying process, making equipment cleaner, environmental protection and energy saving, and greatly extending service life.

We have different hot air generating device for you. According to your Heat Source, no matter it is natural gas, bio-gas, coal, oil, bio-mass fuel or others, we match furnace, chamber, burner etc to be most suitable. What's more, the boiler flue gas can also be used as heat.

The sludge dryer is suitable for electroplating sludge, heavy metal sludge, leather sludge, chemical sludge, printing and dyeing sludge, textile sludge, pharmaceutical sludge, paper sludge, sewage plant sludge, municipal sludge, industrial hazardous waste sludge, alkali sludge, slag and other materials drying.

It is widely used in electroplating enterprises, metal processing enterprises, paper enterprises, textile printing and dyeing enterprises, pharmaceutical plants, sewage treatment plants, chemical enterprises and other industries.

Scrubber

Scrubber systems (e.g. chemical scrubbers, gas scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams.

The exhaust gases of combustion may contain substances considered harmful to the environment, and the scrubber may remove or neutralize those. A wet scrubber is used for cleaning air, fuel gas or other gases of various pollutants and dust particles. Wet scrubbing works via the contact of target compounds or particulate matter with the scrubbing solution. Solutions may simply be water (for dust) or solutions of reagents that specifically target certain compounds.

Cyclone Dust Collector

Centrifugal cyclone dust collector, the dust will be separated and recovered in the drying system, through the dry tail gas dust purification device of a cyclone dust collector, suitable for high dust concentration, large dust particles of exhaust gas dust removal operations, the dust collector has a simple structure, stable and reliable operation, long service life, and other characteristics.

Baghouse

A bag house, also known as a bag house filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air.

Most baghouses use long, cylindrical bags (or tubes) made of woven or felted fabric as a filter medium. For applications where there is relatively low dust loading and gas temperatures are 250 °F (121 °C) or less, pleated, non woven cartridges are sometimes used as filtering media instead of bags.

Bag houses are very efficient particulate collectors because of the dust cake formed on the surface of the bags. The fabric provides a surface on which dust collects through the following four mechanisms:

Inertial collection – Dust particles strike the fibers placed perpendicular to the gas-flow direction instead of changing direction with the gas stream.

Interception – Particles that do not cross the fluid streamlines come in contact with fibers because of the fiber size.

Brownian movement – Sub micrometre particles are diffused, increasing the probability of contact between the particles and collecting surfaces.

Electrostatic forces – The presence of an electrostatic charge on the particles and the filter can increase dust capture.

A combination of these mechanisms results in formation of the dust cake on the filter, which eventually increases the resistance to gas flow. The filter must be cleaned periodically.

1. Design of high humidity and high viscosity sludge

In order to achieve the purpose of non sticking and non sticking, the internal structure of sludge dryer has been upgraded and modified by ZJN. Through the combined lifting device, the material moves at high speed under centripetal force, and is gradually breaked into smaller particles, and fully contacts with hot air, increases heating energy utilization and drying speed, and avoids sludge sticking to the wall of the cylinder.

2. Energy saving and low operating cost

The special multi-loop structure makes ZJN sludge dryer occupy less land area and effectively reduce the investment in infrastructure. In addition, the equipment has good thermal insulation performance and small heat loss. Compared with the traditional single drum equipment, fuel consumption is greatly reduced and the equipment operation cost is low.

3. Clean and dry, environmental protection up to standard

The equipment has good sealing performance, no dust particles overflow during drying process, and the production environment is clean. The waste gas can be discharged after being collected and filtered by exhaust gas collecting system, cyclone and baghouse (bag dust collector), and can meet the environmental protection standards. The user can use it without worry.

4. The entire drying system is centralized control by ABB/Simens PLC, easy to operate. In the drying equipment, drying, crushing, sieving and conveying process are combined to operate. The whole process is simplified and easy to control automatically. Fully automatic, easy and stable operation.

5. High thermal efficiency, long drying time, large treatment capacity. Down-flow in the first stage cylinder, counter-flow in the second stage cylinder, down-flow in the third stage cylinder, W+S type material transfer trend. Material mixed well with hot air. What’s more, the hot air volume can be distributed into three cylinder drum in different volume according to the wet material mositure content, which we use high mositure content, high air volume and temperature; medium himidity choose moderate volume and temperature; low humidity uses small volume and low temperature, making the material can be always in the ideal drying environment.

6. Drying equipment continuously working 24 hours, continuously feeding wet material and continuously discharging finished product.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.