All Dryers Are Customized

Engineers available to offer overseas service

All Year Round After Sale Hotline

Free Remote Technical Support and Train

Warranty: 1 Year

Certification: ISO9001

Application: Living Wastes, Organic Wastes, Rubbin, Food Waste, Sawdust, Vegetable Wastes, PVC, Paper, Dung, Manure,Packaging, Grass clippings, Furniture, Clothing, Bottles,Food Scraps, Newspapers, Appliances, Paint, and Batteries etc.

Before Drying

After Drying

Municipal solid waste consists of everyday waste items discarded by the public that may include product packaging, grass clippings, furniture, clothing, bottles, food scraps, newspapers, appliances, paint, and batteries etc. Nowadays, the economic development and urbanization enable people to enjoy enriched material lives, but subsequently result in more solid waste generated. According to a recent report from World Bank, the current global annual municipal solid waste generation level will increase from about 3 1.3 billion tons by 2011 to about 2.2 billion tons by 2025. Traditional municipal solid waste disposal methods, including landfilling and incineration, are unsustainable, as they use up land which can be otherwise used for arable farming and lead to loss of resources which could be recycled. In recent years, many countries and regions have implemented restrictions on landfilling and incineration of solid wastes. Those restrictions have proved to be effective to in encouraging higher recycling rates for municipal solid waste.

Depending on its composition and heating value, municipal solid waste can be used as a fuel for a variety of industrial purposes.

Municipal Solid Waste dryer is designed for any garbage, refuse, sludge from a wastewater treatment plant, water supply treatment plant, or air pollution control facility and other discarded materials . The drying production is as high as 10 tons/h, the energy saving effect is significant, and the maintenance cost is very low.

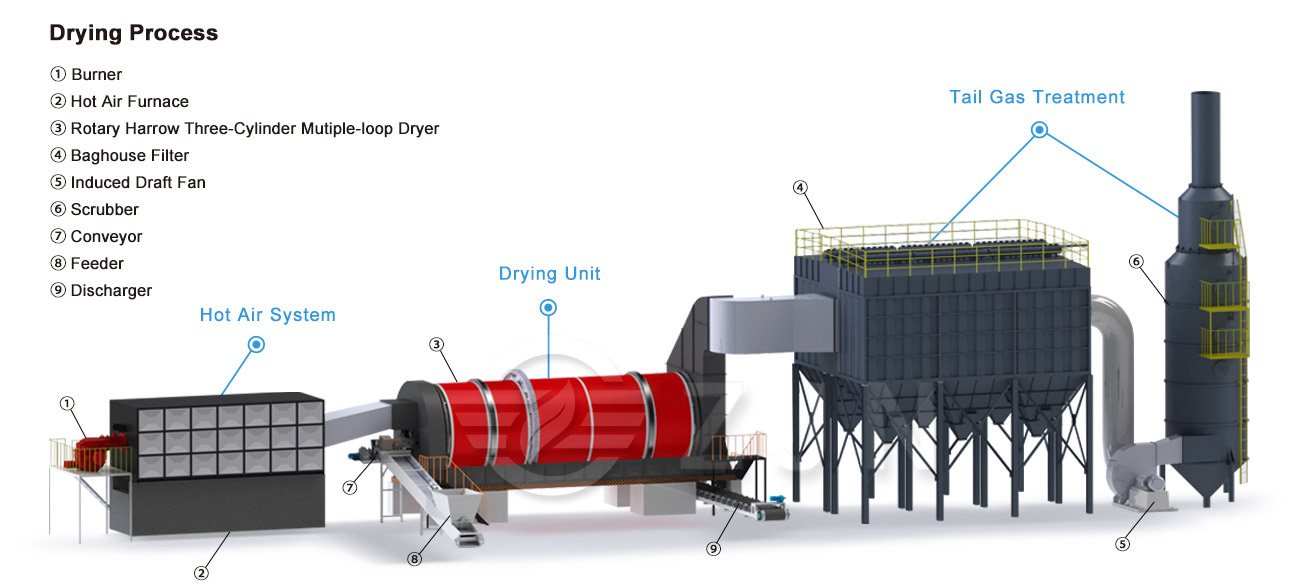

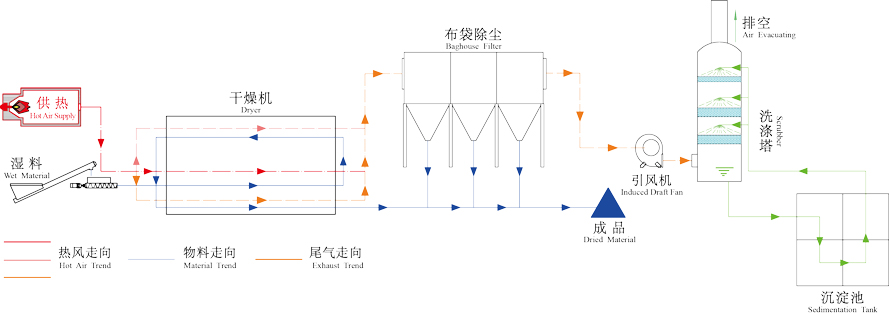

Municipal Solid Waste enter into drying unit. With the joint action of positive and negative guiding and lifting boards and rotary drums, the material boiling in the cylinder and fully in touch with hot air until completing the drying process. Material is highly dispersed in the air flow, the total particles surface is effective drying area. Solid Waste in the drying unit moves as “W + S”-type reciprocating trend, the total stroke is 6 times the ordinary dryer. Large drying space, multiple positive and negative plates, so that the processing amount being increased. Material moving trends and hot air trends in three cylinders respectively are same, reverse, same. In the inner drum, downstream will speed up the surface drying rate, to prevent the material sticky wall; In middle drum, counter flow deepens combined water drying; in the outer drum, downstream drying further so that the solid waste dry evenly. And the material meet drying requirements quickly discharged. Three cylinder sets together, the outer cylinder preserve heat of inner cylinders, the shell also has insulation layer, the thermal efficiency can reach to 80%.

Municipal Solid Waste dryer is widely used at home and abroad. The use of high-temperature fast drying process. High degree of automation, good quality of end products. Setting fire safety devices, hot air waste heat utilization and other devices. Large output, low cost, safe and reliable.

ZJN solid waste rotary drum dryer can effectively solve the problem of solid waste pollution, and realize the reduction, harmless, stabilization and resource treatment and disposal of solid waste. After drying, the solid waste is convenient for subsequent treatment, so that the solid waste can be recycled, turned into treasure, and improve its use value and economic value.

Jiaozuo ZJN environmental protection equipment Technology Co., Ltd. is committed to industrial solid waste, sludge, feed residue and other high humidity and high viscosity materials drying technology research and development and innovation. At present, the company has made more than 100 drying technologies such as "rotary harrow three-stage multi-loop" and "low temperature and large air volume" rotary drum dryer. According to the actual production needs of users, we can make suitable equipment production plans for users to meet the basic and personalized production needs for users.

ZJN solid waste dryer adopts three cylinder structure, that is, the use of three different diameters of the cylinder set together. The internal use of the equipment barrel "three-stage positive and negative lift, guide material" and "W+S" three-stage walking process, can make the material in the barrel repeatedly do back and forth movement, which is the so-called "3 steps to go 2 steps back"; The internal storage of the equipment is large, which is 3 times than that of the traditional single drum dryer; Heat transfer range is wide, the area is 4-5 times of the traditional dryer; Drying distance is long, is also 6 times than that of the traditional dryer; This greatly improves the utilization of heat energy space. The guiding material system and anti-missile material system inside the dryer promote each other, complement each other, constitute the whole chain effect system, linkage and integrated operation.

We have different hot air generating device for you. According to your Heat Source, no matter it is natural gas, bio-gas, coal, oil, bio-mass fuel or others, we match furnace, chamber, burner etc to be most suitable. What's more, the boiler flue gas can also be used as heat.

The rotary drum dryer is suitable for drying solid food waste, kitchen food waste, industrial solid hazardous waste, municipal solid waste, sludge, feed residue and other materials. The drying equipment can be widely used in agriculture, catering, municipal, chemical, electroplating, steel, pharmaceutical, leather, textile and other industries.

Scrubber

Scrubber systems (e.g. chemical scrubbers, gas scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams.

The exhaust gases of combustion may contain substances considered harmful to the environment, and the scrubber may remove or neutralize those. A wet scrubber is used for cleaning air, fuel gas or other gases of various pollutants and dust particles. Wet scrubbing works via the contact of target compounds or particulate matter with the scrubbing solution. Solutions may simply be water (for dust) or solutions of reagents that specifically target certain compounds.

Cyclone Dust Collector

Centrifugal cyclone dust collector, the dust will be separated and recovered in the drying system, through the dry tail gas dust purification device of a cyclone dust collector, suitable for high dust concentration, large dust particles of exhaust gas dust removal operations, the dust collector has a simple structure, stable and reliable operation, long service life, and other characteristics.

Baghouse

A bag house, also known as a bag house filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air.

Most baghouses use long, cylindrical bags (or tubes) made of woven or felted fabric as a filter medium. For applications where there is relatively low dust loading and gas temperatures are 250 °F (121 °C) or less, pleated, non woven cartridges are sometimes used as filtering media instead of bags.

Bag houses are very efficient particulate collectors because of the dust cake formed on the surface of the bags. The fabric provides a surface on which dust collects through the following four mechanisms:

Inertial collection – Dust particles strike the fibers placed perpendicular to the gas-flow direction instead of changing direction with the gas stream.

Interception – Particles that do not cross the fluid streamlines come in contact with fibers because of the fiber size.

Brownian movement – Sub micrometre particles are diffused, increasing the probability of contact between the particles and collecting surfaces.

Electrostatic forces – The presence of an electrostatic charge on the particles and the filter can increase dust capture.

A combination of these mechanisms results in formation of the dust cake on the filter, which eventually increases the resistance to gas flow. The filter must be cleaned periodically.

1.The drying equipment of three cylinder structure, the inner volume of the cylinder is three times than that of the single cylinder drum dryer, and the processing capacity is three times that of the single cylinder rotatry drum dryer.

2. Special dispersing device is installed inside the cylinder of solid waste dryer equipment, which can continuously disperse and stir the materials sent to speed up the mixing contact between materials and hot air, so as to improve the utilization rate of heat energy and improve production efficiency.

3. Automatic control, simple and convenient operation, only 1-2 people can complete the entire production line work tasks.

4. The equipment performance is stable, can run continuously production, and the equipment failure rate is low, the maintenance cost is low.

5. The whole drying system is tightly sealed, and the cylinder body has an insulating layer, which can effectively reduce the loss of heat inside the cylinder and save energy consumption.

6. The dust removal system of solid waste rotary drum dryer is equipped with professional dust removal device, which can filter, purify and dust generated in the production process, so as to meet the requirements of gas emission and ensure a clean and tidy production environment.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.