All Dryers Are Customized

Engineers available to offer overseas service

All Year Round After Sale Hotline

Free Remote Technical Support and Train

Warranty: 1 Year

Certification: ISO9001

Application: sludge,Slime,Coke,pulp,Lees,Organic Fertilizer

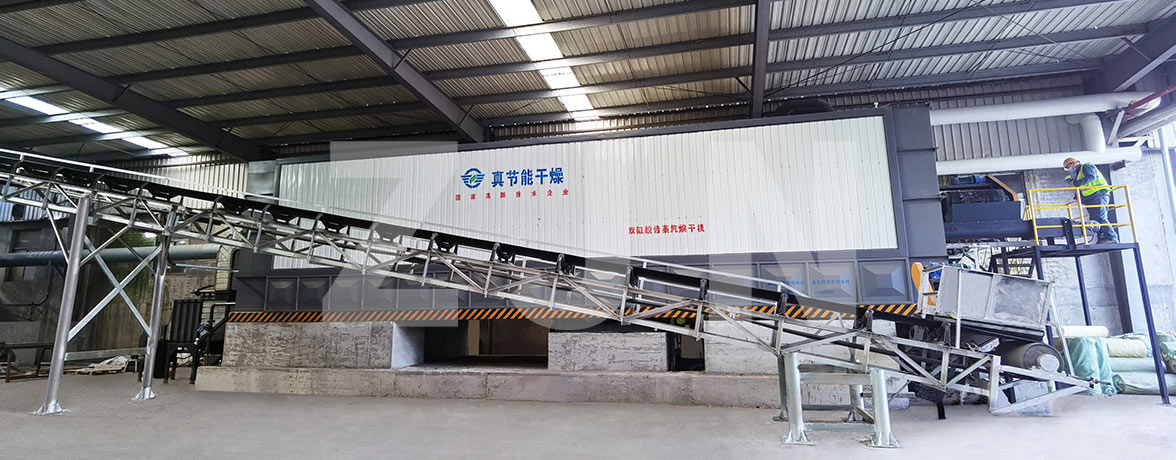

Steam dryer is an important equipment in drying production line, and it is also the main place for drying materials. In addition, the steam sludge drying production line also includes hot stove, dust removal equipment, belt conveyor or bucket elevator, induced draft fan, feeder, feeder, discharger, PLC power distribution cabinet, etc.

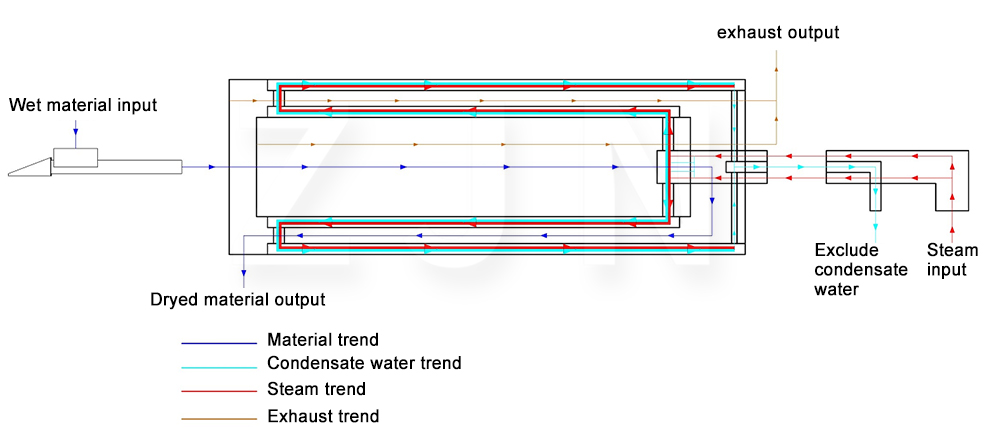

ZJN keeps up with the drying demand of the market, and independently develops the drying equipment with steam as the heat source - "double barrel rake reciprocating multi loop" steam dryer. The equipment uses steam as drying medium and adopts various steam drying technologies. According to the characteristics of different materials (moisture content, viscosity, water binding state, acidity and alkalinity, etc.) and different drying requirements, it can be elaborately designed through the organic combination of the guiding and lifting device (downstream, countercurrent, reciprocating) and the "rake" breaking device and other linkage processes. It realizes the customer's practical demand of drying a variety of materials, especially high humidity and high viscosity materials, using steam as heat source.

In order to meet the drying needs of different users, ZJN provides intimate equipment customization services. According to the user's plant area, production output, water content requirements, material characteristics and other conditions, we can design and customize appropriate sludge drying scheme and waste gas treatment scheme, so that users can use it more easily.

Based on the "rotary rake Feiteng three-stage multi loop" dryer, the "double drum rotary rake reciprocating multi loop" steam dryer is a new type of steam dryer developed by ZJN company who learn from the successful models and experiences of various steam drying processes at home and abroad, through careful research and development, independent innovation design and repeated test, which uses steam as the heat source to dry a variety of materials, especially high humidity and high viscosity materials It is a new steam drying technology.

"Double drum rake reciprocating multi loop" steam drying has the dual functions of heat exchange and drying; all the material guiding, lifting and rake devices in the equipment, including the inner and outer cylinders, participate in the heat transfer together, so the heat exchange area increases geometrically, and the heat utilization rate also increases significantly; there is no dead angle in the equipment to ensure that the materials are always in motion; The process has the advantages of novel design, advanced technology, reliable operation, convenient operation, uniform drying and ideal effect.

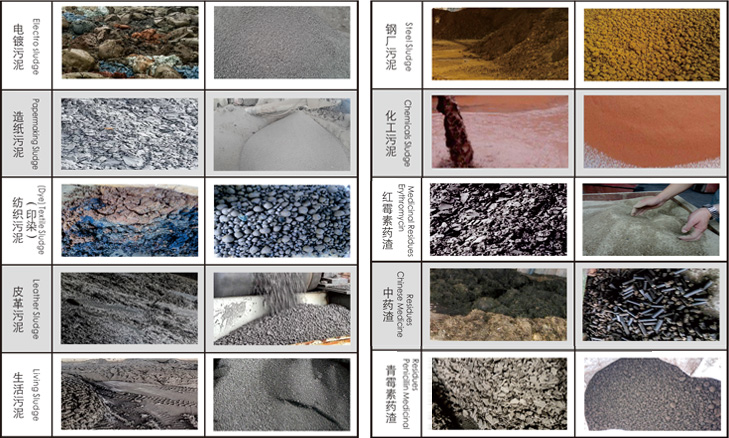

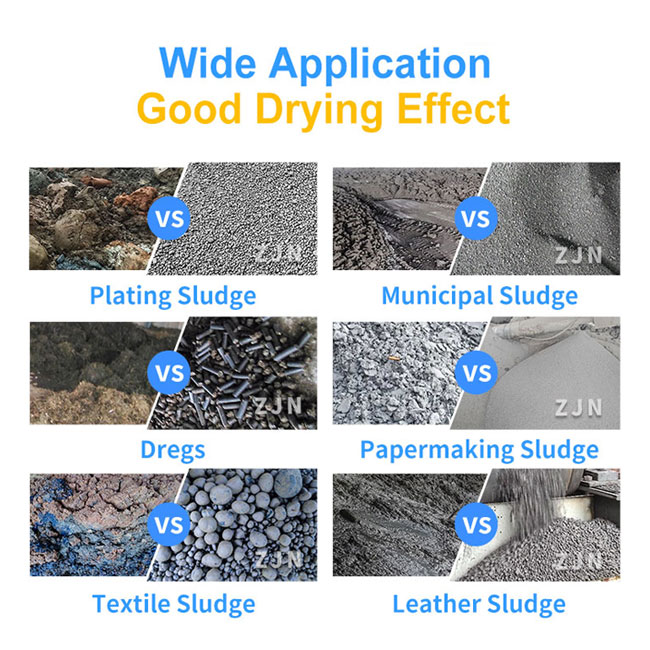

It is suitable for drying high humidity and high viscosity sludge such as electroplating sludge, heavy metal sludge, leather sludge, chemical sludge, printing and dyeing sludge, textile sludge, pharmaceutical sludge, papermaking sludge, sewage sludge, municipal sludge and industrial hazardous waste sludge, as well as distiller's grains, alcohol residue, vinegar residue, soy sauce residue, soybean residue, potato residue, fruit residue, medicine residue, vegetable residue, bagasse, tea residue, starch residue and kitchen waste The waste and other feed dregs are dried.

Widely used in electroplating enterprises, metal processing enterprises, paper enterprises, textile printing and dyeing enterprises, pharmaceutical factories, sewage treatment plants, chemical enterprises, pharmaceutical, brewing, starch processing, biological fermentation, feed and other industries.

Scrubber

Scrubber systems (e.g. chemical scrubbers, gas scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams.

The exhaust gases of combustion may contain substances considered harmful to the environment, and the scrubber may remove or neutralize those. A wet scrubber is used for cleaning air, fuel gas or other gases of various pollutants and dust particles. Wet scrubbing works via the contact of target compounds or particulate matter with the scrubbing solution. Solutions may simply be water (for dust) or solutions of reagents that specifically target certain compounds.

Cyclone Dust Collector

Centrifugal cyclone dust collector, the dust will be separated and recovered in the drying system, through the dry tail gas dust purification device of a cyclone dust collector, suitable for high dust concentration, large dust particles of exhaust gas dust removal operations, the dust collector has a simple structure, stable and reliable operation, long service life, and other characteristics.

Baghouse

A bag house, also known as a bag house filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air.

Most baghouses use long, cylindrical bags (or tubes) made of woven or felted fabric as a filter medium. For applications where there is relatively low dust loading and gas temperatures are 250 °F (121 °C) or less, pleated, non woven cartridges are sometimes used as filtering media instead of bags.

Bag houses are very efficient particulate collectors because of the dust cake formed on the surface of the bags. The fabric provides a surface on which dust collects through the following four mechanisms:

Inertial collection – Dust particles strike the fibers placed perpendicular to the gas-flow direction instead of changing direction with the gas stream.

Interception – Particles that do not cross the fluid streamlines come in contact with fibers because of the fiber size.

Brownian movement – Sub micrometre particles are diffused, increasing the probability of contact between the particles and collecting surfaces.

Electrostatic forces – The presence of an electrostatic charge on the particles and the filter can increase dust capture.

A combination of these mechanisms results in formation of the dust cake on the filter, which eventually increases the resistance to gas flow. The filter must be cleaned periodically.

1. Green and clean

Using steam as heat source, it is cleaner and more environmentally friendly than oil, coal and boiler waste heat, and will not produce toxic and harmful gases in the drying process, which reduces the difficulty and burden of tail gas treatment.

2. Good sealing

The whole machine body adopts fully enclosed treatment technology, with sealing devices at both ends, which has good thermal insulation performance, no dust and particles spilling in the drying process, and good working environment for operators.

3. High utilization rate of heat energy

In a short period of time, by increasing the contact area between the material particles and the hot air and strengthening the effect of heat and mass transfer, a large amount of water in the material can be evaporated.

4. Automatic assembly line operation

Air volume, wind speed, heat, wind direction and other parameters to achieve full automatic control, simple operation, high degree of automation, continuous or discontinuous work, less manpower.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.