All Dryers Are Customized

Engineers available to offer overseas service

All Year Round After Sale Hotline

Free Remote Technical Support and Train

Application: Animal Manure Drying, Poultry Manure Rotary Drum Dryer, Organic Waste Drying Equipment, Peat, Animal Wastes, Plant Wastes from Agriculture, and Treated Sewage Sludge, Animal Wastes from Meat Processing, Peat, Manure, Slurry, and Guano etc

Warranty: 1 Year

Certification: ISO9001

Before Drying

After Drying

Manure is organic matter that is used as organic fertilizer in agriculture. Most manure consists of animal feces; other sources include compost and green manure. Manures contribute to the fertility of soil by adding organic matter and nutrients, such as nitrogen, that are utilised by bacteria, fungi and other organisms in the soil. Higher organisms then feed on the fungi and bacteria in a chain of life that comprises the soil food web. Manure from different animals has different qualities and requires different application rates when used as fertilizer. For example horses, cattle, pigs, sheep, chickens, turkeys, rabbits, and guano from seabirds and bats all have different properties.

The poultry industry is one of the largest and fastest growing sectors of livestock production in the world. Storage and disposal of raw poultry manure have become an environmental problem because of the associated air, water and soil pollution. Environmental and health problems such as odor and pathogens that may arise during and after land application of raw manure can be eliminated by drying. Dried manure can be utilized as a feed for ruminants because of its high nitrogen content. Livestock manure management is the central issue for many environmental policies relating to water and air quality.

Cattle, pig, and poultry livestock produce around 120 million tons of manure per year not including those on pasture. This figure is made up from 60.6% solid manure, 38.8% livestock slurry (effluent) and a relatively small amount of poultry droppings. Solid manure is mainly stored in temporary field heaps. In the case of manure storage on the farm, the capacity varies from 45 days to 7.5 months depending on farm size and type of animals, time spent outside the buildings and the geographical location.

Manure is an expected by-product of the livestock industry. If left untreated, manure is just that, manure, while properly processed manure becomes a value-added marketable commodity, also known as fertilizer. Throughout history, people who raise livestock and poultry have used manure as a fertilizer, soil amendment, energy source, even construction material. Manure contains many useful, recyclable components, including nutrients, organic matter, solids, energy, and fiber. With today’s technology, manure can be used more efficiently and in more ways than ever, which should mitigate many of the environmental impacts that result when manure is treated as a waste. Animal wastes which are taken out from the farm are classified into 3 types; solid, slurry and waste water. Solid wastes are treated by drying or composting. Dried wastes are used not only fertilizer but also as fuel for combustion to obtain energy

ZJN drying equipment special for animal manure can be used for drying poultry manure and livestock manure, such as chicken manure, duck manure, goose manure, cow dung, horse manure, pig manure, and so on, which contains 14.5% organic matter and Nitrogen 0.30 to 0.45%, phosphorus 0.15 to 0.25%, potassium 0.10 to 0.15%, crude protein 16-25%. After drying, these organic ingredients will be protected and the value will be also significantly increased. The dry manure/dung can be used as organic fertilizer, as well as feed for turtles, fish, snails, chickens, ducks.

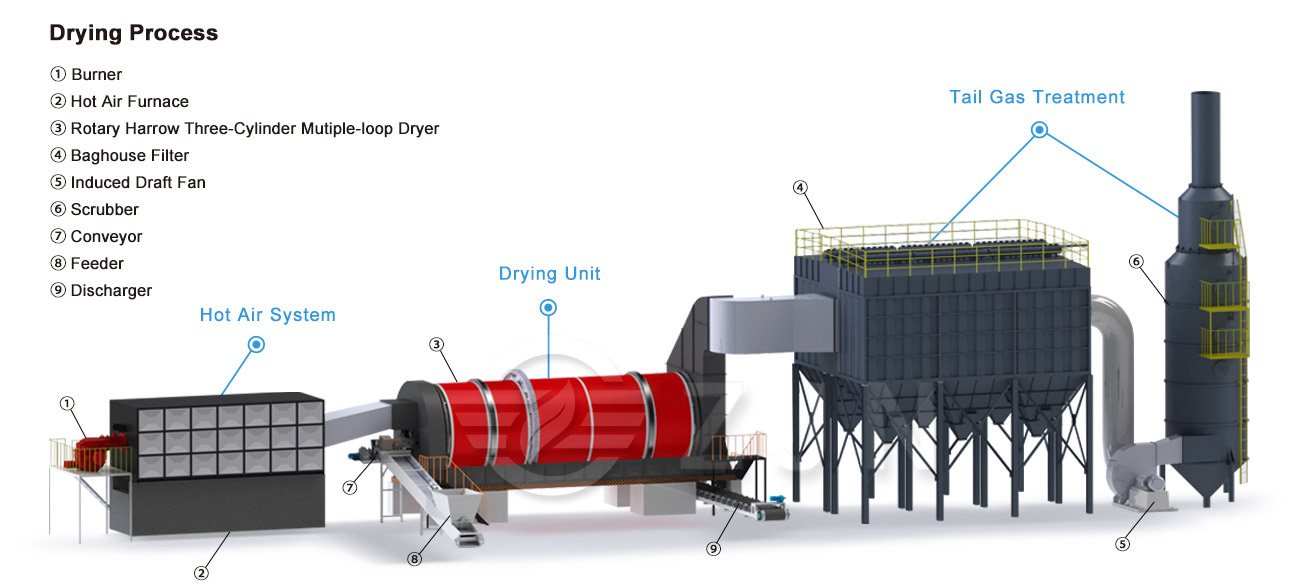

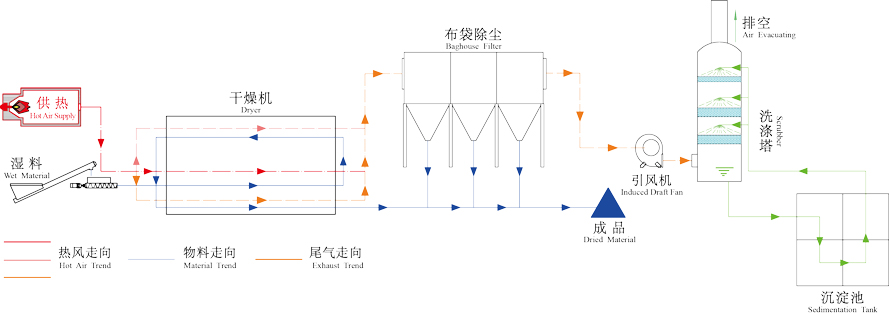

The high viscosity material is fed directly into the rotary drum by the feed screw and is scattered by the lifting board on the inner wall of the drum. During the falling process, materials will touch the rotary harrow and be broken into small pieces, then contact with quickly dry. In the hot air and equipment, driven by the rotation, moved to the other end of the cylinder. The cylinder is equipped with guiding and lifting plates with different arrays and shapes. With the effect of hot air and rotary drum and gravity, materials of high moisture content move forward three steps backward two steps, thus drying in multiple loops. Low water content materials move relatively fast. It ensures that the feces can be evenly dried as required. The whole process is under negative pressure operation, safe and reliable. The sealing system uses micro-contact technology, multiple seals, which prevents air leakage and reduces dust release to the workshop. Water vapor and exhaust gas are discharged in time to prevent re-absorption.

This drying machine also have deodorization device and dust collector, which will efficiently prevent re-pollution of water and land and making benefits for social environmental protection.

Organic fertilizer, also known as "farm manure", not only contains a large number of micro elements needed by plants, but also contains rich organic nutrients, suitable for wheat, rice, peanuts, fruits and other crops to fertilize. Organic fertilize can improve the quality of crops, improve the quality of fruits and melons. It is a good choice of pollution-free green food planting fertilizer.

Organic fertilizer dryer can use chicken manure, duck manure, livestock and other feces, slaughterhouse waste for dehydration and drying treatment, open up feed resources, reduce feeding costs, but also can reduce environmental pollution.

The Organic fertilizer is sent to the first stage dryer with the hot air. In which there is provided with “Rotary Harrow Rolling Crushing Device.” Under the action of this device, the wet materials is broken into the scattered condition, and with constantly rolling, rotating and separating of the material, so that its surface forms a "dry shell", effectively avoiding the particles from agglomerating again. During the constant lifting of the material with continuously flipping, it fills the entire drying space and fully contact with the hot air, then the wet material can be fully utilized the thermal energy and enhance the evaporation of the moisture intensity, and become the loose shape. Thus completing high humidity → not wet, high viscosity → no sticky, high-viscosity→non-sticky important conversion.

Organic fertilizer dryer using "three positive and negative, guide material" and "W+S" three cylinder stage material walking process, can make the material in the equipment to do repeated movement, namely the so-called "three steps back two steps", enhance the evaporation; The storage capacity of the equipment is large, three times that of the traditional dryer.

The heat transfer area is wide, four to five times that of the traditional dryer; The drying stroke is long, six times that of the traditional dryer. In this way, the heat energy and space utilization rate inside the cylinder can be greatly improved, the moisture evaporation inside the material can be accelerated, and the wet material after drying can be guaranteed to be uniform dried, and the finished product quality is good.

We have different hot air generating device for you. According to your Heat Source, no matter it is natural gas, bio-gas, coal, oil, bio-mass fuel or others, we match furnace, chamber, burner etc to be most suitable. What's more, the boiler flue gas can also be used as heat.

Organic manure dryer is suitable for animal manure (such as chicken manure, duck manure, goose manure, cow manure, horse manure, pig manure, etc.), plant residues, animal residues, slaughterhouse waste, cake fertilizer, compost, compost, manure, digestate, green manure and other materials drying.

Widely used in agriculture, feed, fertilizer industry, etc.

Scrubber

Scrubber systems (e.g. chemical scrubbers, gas scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams.

The exhaust gases of combustion may contain substances considered harmful to the environment, and the scrubber may remove or neutralize those. A wet scrubber is used for cleaning air, fuel gas or other gases of various pollutants and dust particles. Wet scrubbing works via the contact of target compounds or particulate matter with the scrubbing solution. Solutions may simply be water (for dust) or solutions of reagents that specifically target certain compounds.

Cyclone Dust Collector

Centrifugal cyclone dust collector, the dust will be separated and recovered in the drying system, through the dry tail gas dust purification device of a cyclone dust collector, suitable for high dust concentration, large dust particles of exhaust gas dust removal operations, the dust collector has a simple structure, stable and reliable operation, long service life, and other characteristics.

Baghouse

A bag house, also known as a bag house filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air.

Most baghouses use long, cylindrical bags (or tubes) made of woven or felted fabric as a filter medium. For applications where there is relatively low dust loading and gas temperatures are 250 °F (121 °C) or less, pleated, non woven cartridges are sometimes used as filtering media instead of bags.

Bag houses are very efficient particulate collectors because of the dust cake formed on the surface of the bags. The fabric provides a surface on which dust collects through the following four mechanisms:

Inertial collection – Dust particles strike the fibers placed perpendicular to the gas-flow direction instead of changing direction with the gas stream.

Interception – Particles that do not cross the fluid streamlines come in contact with fibers because of the fiber size.

Brownian movement – Sub micrometre particles are diffused, increasing the probability of contact between the particles and collecting surfaces.

Electrostatic forces – The presence of an electrostatic charge on the particles and the filter can increase dust capture.

A combination of these mechanisms results in formation of the dust cake on the filter, which eventually increases the resistance to gas flow. The filter must be cleaned periodically.

1. The whole production line design is reasonable, can be built and installed according to the user's actual land area, which can reduce the actual occupation area.

2. The equipment has a high degree of mechanization and can operate continuously; Strong processing capacity, high production efficiency.

3. The equipment performance is stable, few breakdowns, low maintenance costs.

4. The equipment adopts hot air distribution system, which can automatically adjust the temperature and air volume according to the different moisture content of wet organic fertilizer material during the process of drying, greatly saving energy consumption. At the same time, the outer wall of the cylinder is provided with a thermal insulation layer, which protects heat from loss and increases its sealability.

5. The whole drying process is not flammable, high safety performance.

6. The moisture content and particle morphology of the dried material can be adjusted according to the requirements of the user, which is convenient for the next resource reuse.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.