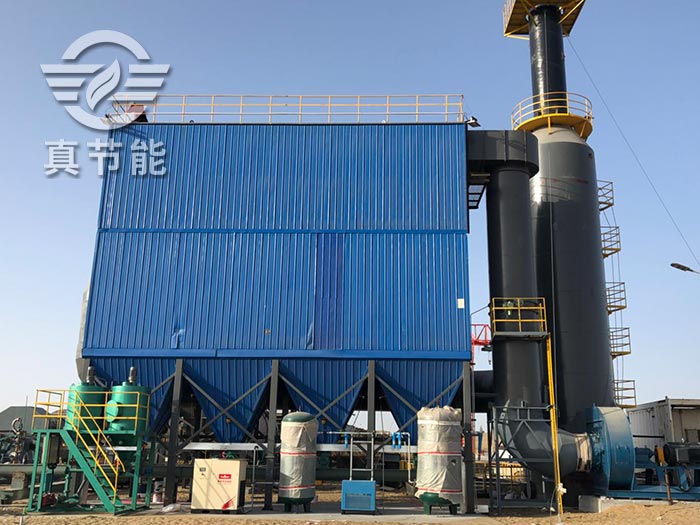

Note: Bag filter is a dry dust remover,suitable for collecting dry non-fabric fine dust. The filter-bag is made of woven filter cloth or non-woven felt, to filter the dust-bearing gas by filtration effect of the fiber fabrics. When dusty gas passes through the bag filter, larger and heavier particles deposit in the ash bucket while smaller particles are blocked when passing the filter material, thus the gas is purified.

It`s necessary to maintain the bag filter to avoid problems in daily work. This article is about causes and solutions of high differential pressure and low dust removing efficiency.

1. Causes and solutions of high differential pressure

A. Worn Out of Filter Bags

After a period of time, filter bag will be worn out by the dust, and pinprick like holes will appear, which will increase the dust concentration of discharged gas. When the airflow containing more dust passes through the fan at a high speed, it will form a major wear of the fan casing and the impeller. Filter bags should be frequently checked about the damage condition. If only a few filter bags are worn out, the dust concentration can be ensured with iron cover to seal the holes on the tube sheet. If it is necessary to replace the filter bag, it is suggested to replace all the bags at the same time to ensure that each filter bag has the same resistance.

B. Air Leakage of Bag Filter

It`s difficult to find the leakage point by naked eye. When checking, it is necessary to open the exhaust fan and close the air door. The leakage point is where hiss can be heard. It should be welded immediately. The aging soft hose between the ventilation pipe, the reversing valve and the promotion valve should be replaced in time to prevent aging and damage.

C. Too High Wind Speed of Bag filter

High concentration of dust will cause high filtration speed, thus leading to the large differential pressure. At this time, the dust removal load of the bag filter and the filtering wind speed of the filter material should be appropriately reduced, that is, the filtration area is increased, and the filter material filtering wind speed is lowered.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.