With the rapid development of social economy and the improvement of human living standard, the annual sludge production in China is gradually increasing. According to its source, sludge can be divided into municipal sludge, industrial sludge and dredging sludge. Municipal Sludge mainly comes from sewage treatment plant or water plant; industrial sludge mainly comes from the sludge produced in the production process of various industries; dredging sludge mainly comes from the sludge produced in the treatment of urban odor water and river dredging.

Characteristics of sludge: first, high moisture content; second, high organic content, easy to produce odor; third, high content of heavy metals; fourth, a large number of bacteria. If these sludges are discarded and buried without treatment, it will cause great harm to the environment and indirect harm to human health.

The significance of sludge drying is that it can reduce the water content and sludge volume in sludge, and at the same time, high temperature drying can kill harmful bacteria in sludge and facilitate sludge recycling. That is to say, sludge drying treatment is an important link in the utilization of sludge resources.

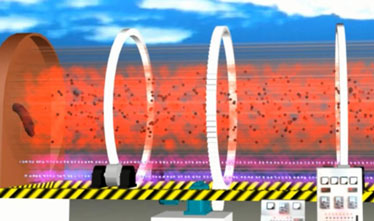

The drying methods of sludge include hot drying, electric drying, microwave drying, solar drying, etc., among which the hot drying technology is mature and reliable, and the production efficiency is high. Heat drying is to use heat medium (high temperature flue gas, heat transfer oil and steam, etc.) to evaporate the water in sludge.

Heat drying can be divided into direct drying and indirect drying according to different heat exchange methods.

Direct drying means that the hot medium directly contacts with sludge to dry. The advantages of the method are: high heat transfer efficiency, fast water evaporation; high solid content of the dried sludge. The disadvantages are: the thermal medium is in direct contact with the sludge, which is easy to be polluted, and the waste gas generated can only be discharged after special treatment; the process is complex, and the odor generated is difficult to control; the dust content is high, which is easy to produce explosion.

Indirect drying is a drying process in which the thermal medium does not contact the sludge directly. The advantages of this method: small amount of tail gas, high environmental protection performance; low dust concentration, small oxygen content and safe. The disadvantages are low heat transfer efficiency, slow water evaporation and low production efficiency.

When users purchase sludge dryer, do not blindly pursue, which dryer is good, which one to choose. To meet their own production needs to choose suitable drying equipment, so as to ensure production.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.