In the past, it was easy to cause serious damage to the surrounding environment when the rotten and malodorous sludge was simply buried or piled up in the open air. The harmful substances in the sludge infiltrate into the soil, which will destroy the soil structure and lose its vitality. The organic matter in the sludge will release toxic and harmful gases and dust after decomposition, which will aggravate the environmental pollution, thus threatening people's physical and mental health. Therefore, it is necessary to use the sludge drying machine to carry out reasonable and scientific dewatering treatment of the sludge.

In the drying and dewatering process of high moisture and high viscosity sludge, the surface water, internal water and cell water in the sludge are quickly evaporated, and the volume of sludge losing water is greatly reduced, showing a loose state with stable chemical properties. It is not only convenient for transportation, but also can be used in various fields to realize the reuse value of resources. So what is such a sludge dryer made of?

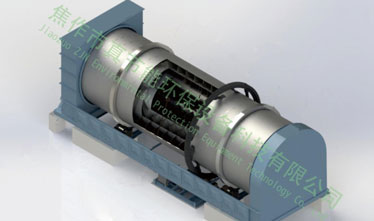

1. Cylinder part: from the appearance, the three sleeve sludge drying machine is composed of three concentric cylinders nested with each other. The special structure extends the drying stroke of materials in the cylinder, and has high drying efficiency, good heat preservation performance and energy saving during operation.

2. Loading and unloading device: the wet sludge is fed evenly through the feeding and feeding system, and the material is continuously fed into the dryer cylinder. After three stages of forward flow, counter flow and mixed flow in the cylinder, the dried materials are automatically discharged from the discharge end.

3. "Rotary harrow crushing" device: the easy to stick large sludge broken, and in the process of high-speed movement, continuous evaporation of water, so that the material into a non stick non stick bulk.

4. Combined lifting plate: make the sludge move at high speed in the sludge drying machine barrel, increase the contact area between hot air and materials, speed up the drying process and improve the thermal efficiency.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.