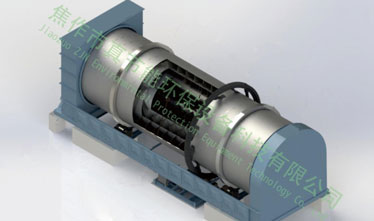

Three drum sludge drying equipment uses fully closed direct heating drying process to dewater and dry the sludge. The special three-layer sleeve structure, rotary rake crushing device, combined lifting system and "W + s" feeding technology can effectively improve the drying efficiency, reduce energy consumption, and realize the reduction, harmlessness and stabilization of high humidity and high viscosity sludge. The equipment has the characteristics of energy saving and environmental protection, and is widely used in electroplating, metal processing, papermaking, sewage treatment, chemical, printing and dyeing, pharmaceutical and other fields. Generally speaking, in addition to the drying host, customers also need to be equipped with a complete set of drying production line facilities when purchasing equipment. Where can I buy equipment with high cost performance and professional technology?

1、 Complete sludge drying production line

A complete sludge drying production line mainly includes heating equipment, drying host, waste gas treatment equipment, feeding and feeding system, induced draft fan and other equipment. These equipment complement each other to complete the work of sludge drying treatment.

In recent years, with the development of drying technology, the forms of drying equipment have changed greatly, including disc type, belt type, centrifugal type, fluidized bed, three-layer drum type, etc. The feeding mode can also be divided into dry wet mixing type and wet sewage direct feeding. These different drying processes are suitable for different sludge characteristics and various drying requirements. For example, the three-layer drum type sludge drying equipment can be applied to the drying of high humidity and high viscosity sludge, with a daily output of 100 tons, which is very suitable for sludge dewatering in large and medium-sized enterprises.

2、 Where can I buy qualified sludge drying equipment

1. Through online search, friend introduction and other ways, we can roughly select several manufacturers with good reputation, and get some basic information of equipment and manufacturers through online communication.

2. Go to the manufacturer for on-the-spot investigation to understand the equipment process, manufacturing technology, quality control, manufacturer strength, price, etc. through several comparison, comprehensively consider and select the equipment manufacturer with higher cost performance.

At present, most of the sludge drying equipment manufacturers are located in Henan, Shanghai, Guangdong and other places. There are many large-scale equipment manufacturers in Henan Province. Among them, ZJN environmental protection equipment has been in the drying field for more than 30 years. With reliable quality, stable performance and perfect service, it is an ideal target for purchasing sludge drying equipment.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.