Drum sludge drying equipment can be used to dehydrate and dry municipal sludge, domestic sludge, chemical sludge, electroplating sludge, metal sludge, oil sludge, coal sludge, tannery sludge, pharmaceutical sludge, papermaking sludge and textile sludge. With the attention of all walks of life to environmental protection, the sales volume of drum sludge drying equipment in the market is increasing day by day.

Design principle of drum sludge drying equipment

The equipment adopts hot air drying. The sludge enters the interior of the drying equipment through the feeding device. Under the action of hot drying medium, the steam pressure on the surface of the dry sludge exceeds the steam pressure of the drying medium. In this way, the water in the sludge can be vaporized. The water in the sludge is continuously diffused to the surface, and the surface water vaporizes and evaporates, so that the sludge can be quickly dried. In fact, in the drying process, hot air is the heat carrier needed to evaporate the water in the sludge, and it is also the carrier of moisture that takes away the water evaporated from the sludge surface.

Secondly, the drum speed of drum sludge drying equipment will also affect the sludge drying efficiency and treatment capacity. It is not to say that the faster the drum speed, the higher the drying efficiency. The speed of the drum is also closely related to heat. The faster the speed is, the higher the heat required and the greater the energy consumption. The rotation speed of the drum should be reasonably designed according to the moisture content, drying temperature and air volume of the drying sludge. When users choose equipment again, they need to communicate with manufacturers according to their own requirements, so as to ensure that the selected equipment can not only meet the production requirements, but also ensure the drying efficiency and the quality of finished products after drying.

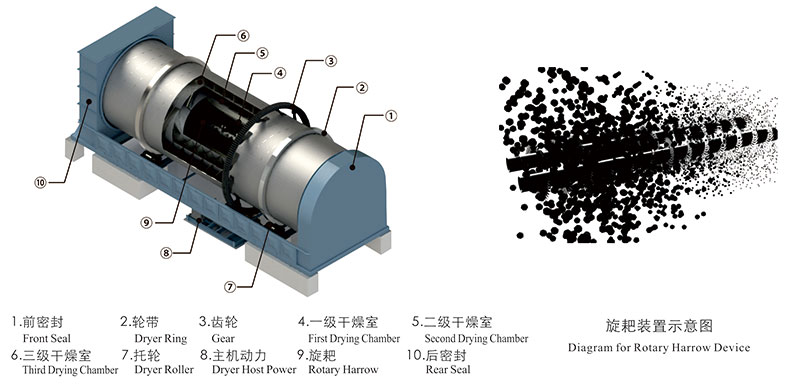

The three-layer drum sludge drying equipment produced by Jiaozuo ZJN company adopts three cylinders with different diameters, which not only increases the storage capacity in the cylinder, but also increases the drying stroke and reduces the floor area. The equipment is also equipped with a hot air distribution system, whose temperature and air volume can be automatically regulated according to the moisture content of sludge in each drying stage, which can not only improve the drying efficiency, but also save energy consumption, at the same time, it can ensure the drying and wetting uniformity of the dried sludge and retain the original tissue composition of the sludge.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.