The waste water sludge dryer is mainly used for the dehydration of high humidity and high viscosity municipal sludge, industrial sludge, river sludge and domestic sludge. The moisture content of the dried sludge is greatly reduced, and the volume is significantly reduced. It can be used for making environmental protection building materials, burning power generation and other purposes, with high utilization price. So how to realize the dehydration and drying of the specific wastewater sludge dryer? This paper introduces the equipment principle of the wastewater sludge dryer one by one.

Equipment principle of waste water sludge dryer

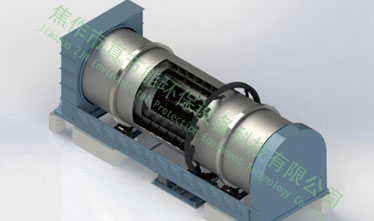

Sludge drying can not only be completed by a dryer, but also needs the cooperation of heating equipment, transportation device, feeding and feeding device, dust removal equipment, instruments and meters, which cooperate with each other to complete the drying operation. The new type of waste water sludge dryer adopts three-layer sleeve structure, mainly uses high-temperature hot-air rapid drying technology for drying and dewatering. It has the characteristics of low cost, simple operation, large output and good drying efficiency.

The high moisture and high viscosity sludge is transported to the dryer cylinder by the conveying device, and is dispersed into fine particles by the "rotary rake crushing" device, and then is continuously lifted and scattered under the rotation of the lifting plates in the drum, forming a uniform material curtain on the cross section of the cylinder, speeding up the contact area of wet sludge and hot air, and strengthening the effect of heat and mass transfer in drying. Materials and hot air in the cylinder along the inner cylinder, the middle cylinder and the outer cylinder in sequence. After three stages of downstream drying, counter current drying and reciprocating drying, the moisture in the sludge is also evaporated. The sludge products which meet the water content requirements are discharged to another discharge valve under the push of the plate. The tail gas discharged from the waste water sludge dryer is collected and purified by dust removal equipment, and then discharged into the atmosphere after reaching or higher than the local environmental protection standards.

In the drying process of waste water sludge, heat exchange is the key step, which not only requires the quality of equipment and rich experience of operators, but also the combined action of material curtain, hot air volume, wind speed, temperature, internal structure layout of drying area and other factors. Only by improving the utilization rate of heat energy and reducing the heat loss can the drying quality be guaranteed.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.