In order to reduce the volume and weight of high humidity and high viscosity sludge, the key problem is sludge dewatering technology. At present, the common sludge dewatering technologies include sludge conditioning, mechanical dewatering, multi return sludge low-temperature dryer drying and so on. Sludge conditioning is to change the nature of sludge dewatering by adding modifier, so as to weaken the binding force between sludge and water; sludge mechanical dewatering uses pressure filter, centrifuge and other equipment to remove part of water by using physical principles. The above two methods can be used as pretreatment methods for sludge drying, but to realize harmless and reduction of sludge, multi return sludge low-temperature dryer is needed. What is the working principle of this equipment and how to realize deep dehydration of high humidity and high viscosity sludge?

Working principle of multi return sludge low temperature dryer:

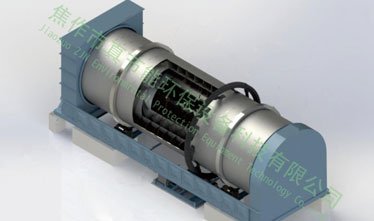

First of all, the structure of the multi return sludge low temperature dryer is composed of three cylindrical rollers nested with each other, and the drum is equipped with a dispersion device and an interleaved lifting device. The wet material is sent into the dryer cylinder through the conveying device and feeding device, and the hot air enters from the same side to complete the whole drying process

1. After the wet sludge enters the cylinder, it is quickly broken into small particles by the dispersing device. The sludge particles are constantly lifted and scattered in the cylinder by the lifting device, and they are centrifuged at high speed to form a uniform material curtain on the cross section of the cylinder.

2. Hot air and materials go in the same direction, wet materials and high humidity hot gas contact, due to the large temperature difference, can quickly evaporate a large amount of water, quickly forming a non stick shell.

3. The hot air and the material go in the opposite direction. The disorder degree is increased, the wet material is heated stably, and the moisture in the wet sludge is further evaporated, which speeds up the drying speed.

4. After heat exchange, the sludge reaches the required moisture content and is in loose state. The dry material that completes the drying process slides to the discharge port.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.