The moisture content of pulp sludge is an important factor to determine whether the dewatering of high moisture and high viscosity sludge is up to standard after being treated by pulp sludge dryer. Therefore, when selecting pulp sludge dryer equipment, paper manufacturers should not only look at the quality of the equipment itself, but also check whether the dehydration degree of the equipment has reached the required water content standard. And from the perspective of environmental protection policies of various departments, the lower the moisture content, the easier it is to meet the requirements of disposal. What are the characteristics of water content change of pulp sludge after being treated by pulp sludge dryer? Next, the small part will introduce it in detail.

Characteristics of sludge before treatment by pulp sludge dryer

The water content of pulp sludge before treatment is very high. The water content in the sludge can be divided into the following four types: 1. Free water, which occupies a large proportion in the sludge, can be separated by mechanical force (centrifugal force, concentration pressure). 2. Capillary water is highly dense around fine sludge particles, and can be destroyed and separated by external forces such as pressure and centrifugal force. 3. Adsorption water, internal bound water, these two kinds of water in the sludge content is not much, but it is difficult to remove. The adsorption capacity of adsorbed water is very strong, and the internal bound water exists in the inner of sludge particles. It is difficult to remove these two kinds of water by ordinary methods, and only by using the high temperature heat of pulp sludge dryer can the two kinds of water be removed.

In general, sludge with water content above 85% will be in flow state, 65% to 85% sludge will be in plastic state, and sludge with moisture content lower than 60% will be in solid state. Before drying, the materials are usually pretreated by dehydrators, centrifuges, filter presses and other equipment, which can reduce the moisture content of the materials. It not only makes use of the subsequent drying operation, but also saves the consumption of heat energy, which is a common method at present.

Characteristics of sludge treated by a real energy saving pulp sludge dryer:

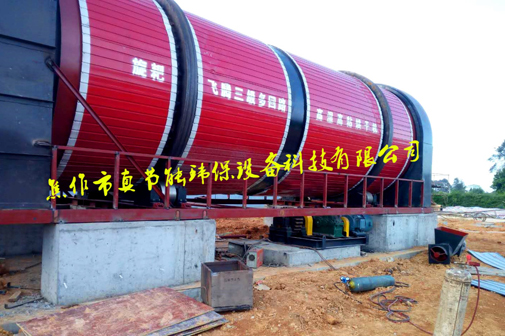

The ZJN three cylinder pulp sludge dryer adopts the principle of high-temperature hot air flow and wet sludge heat transfer. After the wet materials enter the cylinder, they are first scattered into fine particles, and then continuously lifted and scattered under the action of the lifting plate. The uniform material curtain forms on the cross-section of the cylinder, which greatly increases the contact surface area of the sludge particles. After the hot air flow passes through the dryer, the sludge is evaporated A lot of water. The special design of the three-layer sleeve has the advantages of small floor area, energy saving and consumption reduction, and large daily output. The dried pulp sludge is loose, with low moisture content, good color, no paste and good quality. Friends in need can contact ZJN customer service.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.