Steam sludge dryer is commonly used in the drying and dewatering of high moisture and high viscosity sludge, and is the main equipment in sludge treatment and disposal. In order to improve the output and quality of sludge drying, in addition to daily equipment maintenance, the fundamental problem lies in how to select the right steam sludge dryer. So how can friends who want to buy Steam sludge dryer do well in equipment selection?

Selection of steam sludge dryer

1. Consider the scope of application of the equipment

Before purchasing the steam sludge dryer, attention should be paid to the selection of the model of the steam sludge dryer according to different material characteristics. For example, the equipment that can meet the drying requirements should be selected according to the moisture content, viscosity, yield and corrosivity of the materials. In this way, in the drying process, such as transportation, heat transfer, drying, discharge and other aspects will be more applicable. Users can choose the finished equipment or let professional sludge dryer manufacturers customize the size, configuration and process of the equipment. The customized equipment can not only meet the basic drying needs of users, but also achieve the design of energy saving, consumption reduction and environmental protection to a large extent.

2. Consider drying process

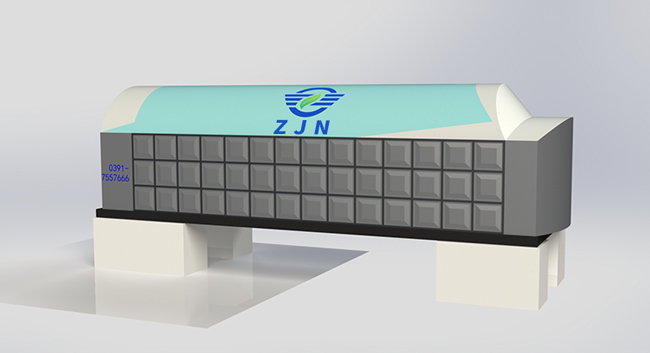

Different steam sludge drying machines adopt different equipment and processes. For example, the "automatic rake reciprocating" steam sludge dryer developed by ZJN environmental protection equipment adopts three-layer sleeve structure, W + s feeding process, special exhaust mode and reciprocating drying technology of three-step and two-step backward, which can improve the utilization rate of heat energy, reduce energy consumption and accelerate drying Drying speed and drying quality.

3. Consider the cost of investment

The investment cost of equipment includes equipment purchase cost and equipment operation cost. The equipment operation cost includes heating cost, depreciation cost, labor cost, equipment maintenance cost, spare parts cost and so on. This requires our users to keep their eyes open and choose reliable manufacturers when purchasing steam sludge drying machines. In this way, the quality, service life, after-sales service and spare parts of the purchased equipment can be guaranteed.

4. Consider environmental requirements.

In the process of sludge drying, production waste gas can not be avoided. Therefore, dust removal equipment is required to collect and purify the waste gas, and then discharge it after reaching or higher than the local environmental protection standards. However, users can rest assured that professional manufacturers will design a scientific and reasonable waste gas treatment scheme to make the equipment more reliable.

ZJN environmental protection equipment Technology Co., Ltd. adopts the experience mode of independent research and development, self-production and self-sale. There is no middleman to earn the price difference. On the basis of ensuring the quality of steam sludge drying machine, the cost performance ratio is very high. If you need any help, you can contact the customer service or visit the factory for consultation.

Copyright ©2022 by Jiaozuo ZJN Environmental Protection Equipment Technology Co., Ltd.